Testliner

Paper Products

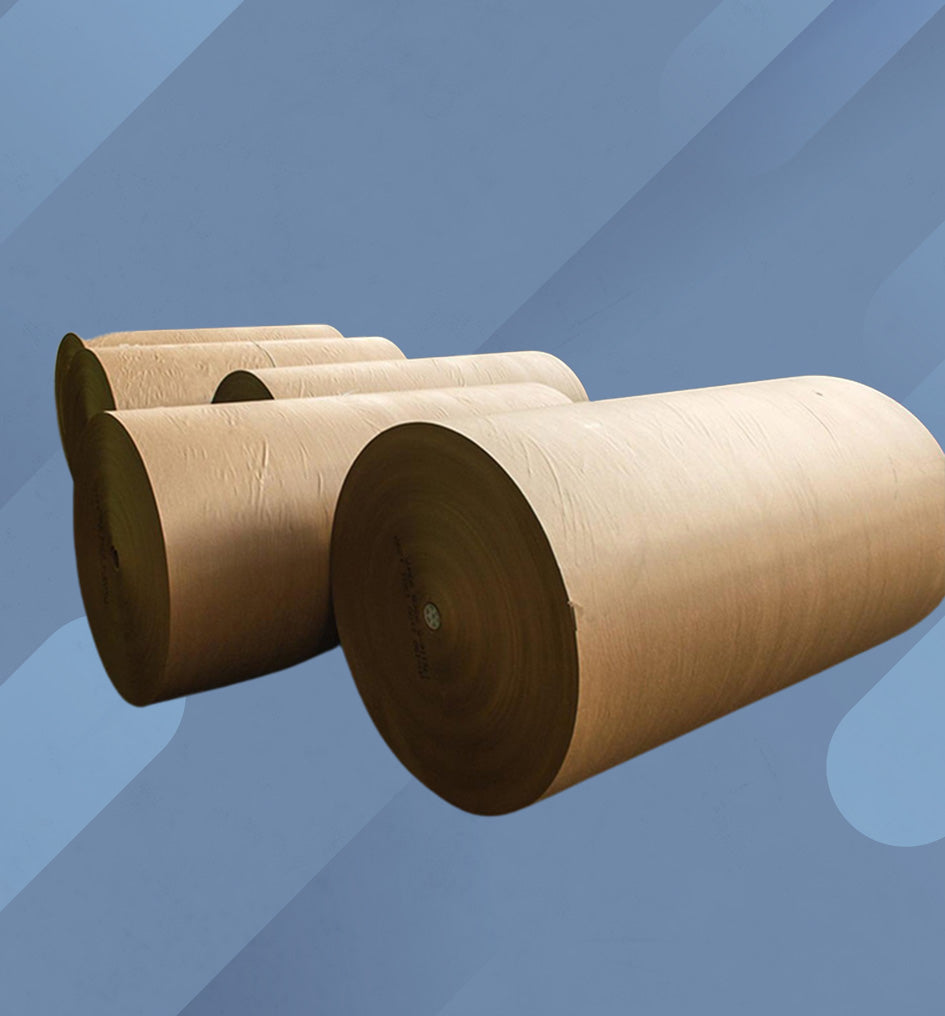

Testliner Paper

Testliner paper is known for its durability and high-quality surface. It is commonly used in packaging and cardboard production.

High Strength: Testliner paper offers high durability, making it suitable for carrying heavy loads and for long-term use. This feature ensures reliability during transport and packaging processes.

Surface Quality: The paper's surface is smooth and even, designed to be suitable for printing and coating processes. This provides both aesthetic and functional use.

Eco-Friendly: Made from recycled materials, it is environmentally friendly and has recyclable properties.

Flexibility: Testliner paper offers flexible use with various thickness and weight options, making it suitable for different packaging and production needs.

High Compression Resistance: It demonstrates high resistance to compression and impacts, protecting products during packaging.

Description

Testliner paper is widely used in the packaging industry. Its superior strength ensures that heavy loads are transported and protected. The surface quality makes the paper suitable for printing and coating processes, resulting in aesthetically pleasing outcomes. Its eco-friendly properties, being made from recyclable materials, offer an added advantage. Furthermore, the flexibility and high compression resistance of testliner paper provide a reliable and durable solution for packaging processes. This paper is preferred for packaging and cardboard production, meeting both functional and environmental requirements.

Usage Areas:

• Packaging: Used for securely packaging and transporting products.

• Cardboard Production: Used in the production of various types of cardboard with different thickness and weight options.

• Labeling: Preferred for labeling and printing due to its high surface quality.

• Discount Packaging: Used in price tags and promotional packaging.

Advantages:

• High Durability: Testliner paper provides ideal durability for transporting heavy loads.

• Eco-Friendly: Made from recyclable and environmentally friendly materials.

• Flexibility: Offers various thickness and weight options, adapting to different needs.

• Compression Resistance: High compression resistance protects products against impacts and compressions.